Railway Motors

Contact Details

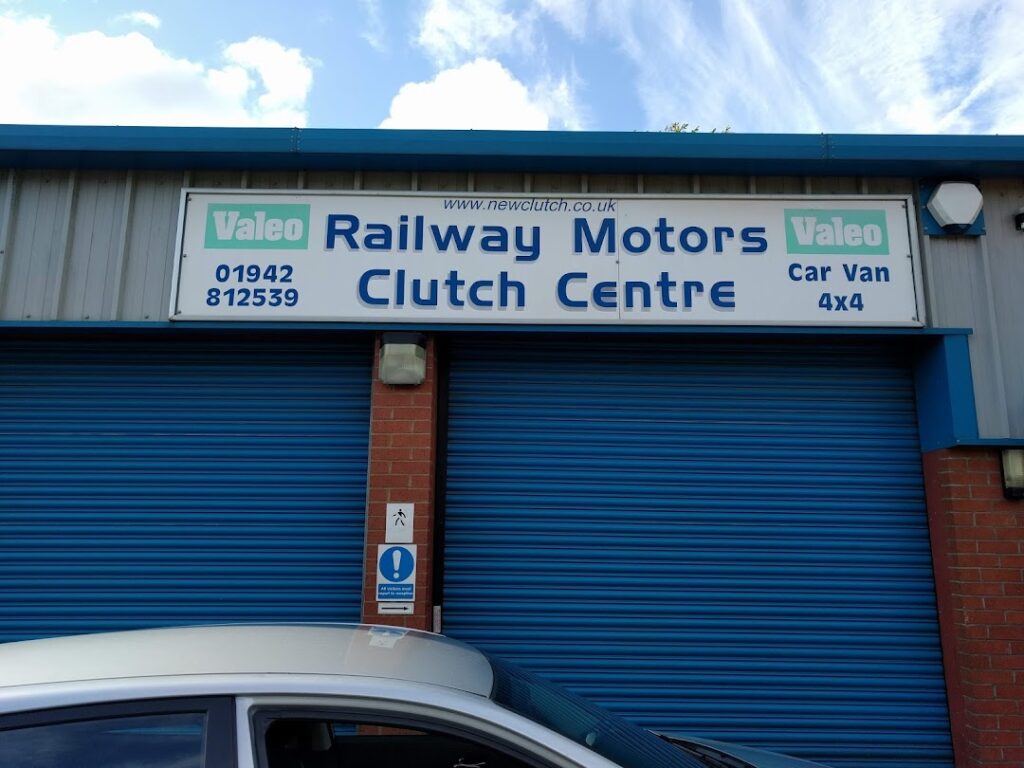

Name: Railway Motors

Address: 228 Church Street

Town: Westhoughton

City: Bolton

County: Greater Manchester England

Postcode: BL5 3QW

Phone: 01942 812539

Mobile: 01942 812539

Website: http://www.railwaymotors.co.uk/

E-mail: N/A

Opening Times

Monday: 08:30 – 17:00

Tuesday: 08:30 – 17:00

Wednesday: 08:30 – 17:00

Thursday: 08:30 – 17:00

Friday: 08:30 – 17:00

Saturday: Closed

Sunday: Closed

Report Incorrect Data

Railway Motors

Railway Motors is a family run business established in 1983 and concentrate solely on the repair and replacement ofclutches , dual mass flywheels and associated components to trade and retail customers on Cars, Vans and 4 x 4 vehicles, so whether you need a simple adjustment or a complete overhaul of the clutch system then contact us for a competitive quote.

All our clutches are brand new original equipment specification units and are sourced from the worlds leading original equipment manufacturers.

e.g :-

- Luk.

- Valeo.

- Sachs.

- Borg & Beck.

- Exedy.

We do not fit reconditioned clutches, (unless they are the only option available) as in our experience remanufactured clutches have a much shorter lifespan than brand new original equipment specification units.

Same day turnaround for 99% of vehicles and a while you wait fitting service is also available.

We also offer a range of Dual mass flywheel conversion kits, comprising of a new solid flywheel, a sprung heavy duty clutch kit and release bearing. Contact us for the latest prices.

Trade enquiries welcome.

Clutch Kits

Typically our clutch kits are supplied in 3 pieces, containing a clutch cover, also known as the pressure plate, a clutch plate and a release bearing.

On vehicles equipped with a concentric slave cylinder (CSC for short) the bearing is an integral part of the slave cylinder and does not come as part of the clutch kit. These are available separately.

It is our recommendation that the CSC is replaced as a matter of course when the clutch is replaced, as subsequent failure of the cylinder results in expensive labour costs and possible damage to the clutch.

Dual Mass Flywheel

Most modern vehicles nowadays, particularly diesel models are fitted with a Dual Mass Flywheel, their purpose is to damp out any engine vibrations for a smoother, quieter drive. (see pic to right)

Worn flywheels are usually accompanied with increased noise levels, particularly during engine start up and when the engine is switched off and increased levels of vibration/harshness.

One side effect, mainly affecting Ford and Vauxhall vehicles is the accumulation of iron filings that are produced as the flywheel wears and this can cause premature starter motor failure.

In our experience and as a rule of thumb, the dual mass flywheel of diesel engined vehicles should always be replaced at the same time as the clutch, on petrol engined cars more often than not they can be re-used, obviously there are exceptions to the rule, eg Mini Cooper S and Golf Turbos.

Valeo have created a range of flywheel conversion kits for some of the most popular models that replace the Dual Mass Flywheel with a Conventional single mass flywheel and a sprung clutch plate, which means that subsequent clutch replacements are much cheaper which makes them ideal for Taxi’s, vans and other high mileage vehicles.

The drawbacks are, an increased level of noise and vibration in comparison to a dual mass setup and increased wear on the gearbox syncromesh as they now have to cope with the increased weight of the sprung clutch plate.

Guarantee

Clutches

- Manufacturers 2 year unlimited mileage Parts and labour guarantee against manufacturing and material defects, unless otherwise stated.

- Dual mass flywheels

- Manufacturers 12 month 12,000 mile parts & labour guarantee (whichever soonest)

- Concentric Slave cylinders

- 12 month 12,000 mile guarantee (whichever soonest)

- Exclusions

- Taxis, Vans, 4×4 vehicles, These come with a 12 month 12,000 mile guarantee (whichever soonest)

- Slipping due to wear & tear , oil contamination, Misuse, abuse or overheating of the friction linings, wear to diaphragm spring fingers. Vehicles not maintained according to manufacturers guidelines (proof may be required). Vehicles modified from the original vehicle specification (eg power upgrade). Parts not fitted at the time of the original repair, . Consequential damage caused by continued use of the vehicle once a fault has become apparent. Parts not supplied by ourselves.